Table of Contents

Between the different color foam pads, wool pads, and microfiber pads, it can be confusing and overwhelming. Even the terms buffing and polishing can be confusing. (They’re really different names for the same thing.) The truth is they’re not quite as complicated as they may initially seem.

Types Of Buffing Pads For Cars

The 3 material types of buffing pads used in paint correction are foam, microfiber, and wool.

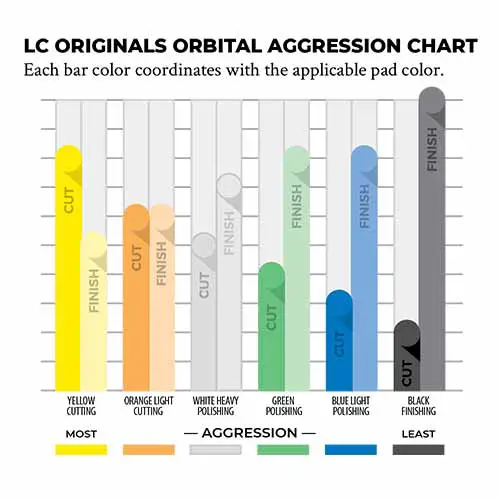

Foam is the most popular and broken down into various color codes. The colors indicate whether they should be used for cutting, polishing or finishing.

Microfiber and wool are more aggressive and mostly used for cutting.

- Foam

- Cutting

- Yellow

- Orange

- Polishing

- Green

- White

- Blue

- Finishing

- Black

- Red

- Cutting

- Microfiber

- Wool

All the different buffing pads are actually meant to make the job of paint correction easier and not harder. Some are meant to be gentle while others are more aggressive for more demanding jobs.

Let’s go over the different polishing pad types and when to use them.

What Are Buffing Pads?

Buffing pads are soft, circular pads used in paint correction for cutting(compounding), polishing, and finishing. The pads can be used manually but most car enthusiasts attach them to a machine polisher. Buffing pads may be used as polishing pads to make a painted finish look smooth and shiny or can be used to apply wax or sealant to the exterior finish of your car.

Cutting

Cutting is the most aggressive buffing process. It will “cut” through your clear coat much more quickly and extra care will be needed to ensure you don’t completely wear through the clear coat and expose the bare paint layer beneath.

Cutting also will leave a more dull appearance when finished and require polishing to bring back the high gloss you’ll want your paintwork to have.

Polishing

Polishing is a much milder process than cutting. It will more gently wear away at your clear coat and leave a silky smooth finish when complete.

Buffing pads are most commonly made of foam, wool, or microfiber. Not only do they give a smooth finish to the exterior of your car, but they also can remove dirt from the surface as well. Buffing pads make great applicators for car polish or wax because they are able to absorb the liquid and give a smooth, even coat to the car.

Finishing

Finishing is mostly the application of a wax or paint sealant. It can also be referred as a final polish with an extremely mild polishing product.

Using a polisher to apply the wax or sealant makes the job much easier and the pads used are designed to be extremely gentle.

What Types Of Buffing Pads Are Available?

There are many different buffing pads available with many different pad features. Depending on the material and color, the pads are meant to perform different types of jobs. Most buffing pads are made from foam, wool, or microfiber.

Each of these materials has cutting (aka compounding) pads, polishing pads, and finishing pads. Let’s take a look at each category, the different materials, and the different colors that are included.

Foam Pads

Foam buffing pads are less aggressive pads and can be used for cutting, polishing, or finishing. A dense foam pad can be used for cutting jobs while a lighter foam applicator pad is good for polishing, waxing, or removing light scratches. They come in different buffing pad colors. Always be sure to use high-quality foam to assure your car’s exterior looks its best.

Cutting

For a light-cutting job like removing a watermark or a scratch from your cars’ exterior, a yellow or orange pad will get the job done efficiently. These are aggressive pads and should be used with care.

Yellow

Yellow pads are the most aggressive type of foam buffing pad. These are used with cutting compounds or polishes and to remove oxidation, scratches, or swirls. If you’re using a yellow foam pad, you shouldn’t finish with it. You have to gradually step down in color since yellow is a heavy cutting pad.

Orange

Orange pads are the second most aggressive type of foam pads. An orange pad is good for moderate car issues such as small defects and scratches on the car. Orange pads are a great go-to pad since they can correct damaged paint and polish your car at the same time.

Polishing

Foam polishing pads come in green, white, and blue. A foam polishing pad is softer than a cutting pad and is the second step in removing surface defects from the car surface. These are less aggressive pads and are frequently used with a polishing compound that has a lower level of aggressiveness.

Green

Green buffing pads are perfect for applying one-step polish, cleaner, or waxes. These pads have a unique compression ratio and conform easily to the curved surfaces of your car. Green pads are frequently used to remove scuffs and swirl marks from your car. In addition, you can create a balance between finishing and polishing with these pads.

White

White foam pads are good as applicator pads when using lighter compounds such as microfine sealants, cleaner waxes, and finishing polishes. It is the preferred pad for pre-wax cleaners because of its light-cutting powers.

Blue

A blue buffing pad results in a very fine finish. It has a unique composition perfect for light surfaces and glazes. Blue pads are great applicator pads for applying glaze, liquid waxes, polishing products, and sealants.

Finishing

Finishing pads come in black and red. They can be considered the last step in restoring and protecting the finish or your car. Use them with a last-step product or with an all-in-one product that has low to no cut or aggressiveness.

Black

Perfect for applying waxes, sealants, and glazes, black buffing pads have no cut in their design. This allows black pads to hold high pressure for applying thin coatings of products. If you’re going to apply carnauba wax to your car, a black buffing pad is a popular choice.

Red

Red buffing pads have no cutting capabilities. A red buffing pad has ultra-soft properties and works well with cars that have sensitive paint coverings. Red pads are perfect for applying high-end waxes and sealants to the paint surface.

Flat Polishing Pads Vs Waffle, Hex, CCS, And Other Textured

Foam Pads

Aside from the foam pads covered above which are considered flat pads, there are a few more foam types with different pad features that you may encounter.

These textured foam pads are generally all attempts to mitigate heat buildup. The voids or high and low spots allow for better heat dissipation. Each will also have their own unique features and benefits you should consider if heat buildup is a concern. For a beginner though, we recommend sticking with foam pads until you start to identify problems that these pads can help solve for you.

Waffle pads have a waffle pattern. They are good for removing light swirl marks, light compounding haze, or towel marks. Waffle pads work well with a finishing polish to create a high-gloss, swirl-free finish on your car’s paint surface.

Hex pads are so named for their hexagonal raised pattern. These pads are aggressive and can remove severe oxidation, swirls, and scratches.

CCS pads, or collapsed cell structure pads, can control the way a product is released on the car’s surface. The structure of the pad is able to collect excess polish and hold it until it is needed. While this increases your work time, it also reduces product waste.

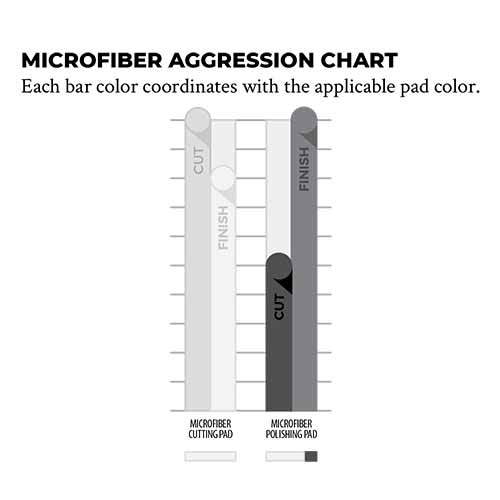

Microfiber Pads

Microfiber buffing pads come right in the middle of foam and wool in terms of aggressiveness. A microfiber pad is good for fixing moderate scratches and for lesser paint correction. Like microfiber cloths, microfiber pads are composed of many strands of synthetic material woven together. Although they are less aggressive than wool, it’s still a good idea to finish up with foam even when using microfiber.

Cutting

The microfiber materials in these pads give a good cutting ability. They can remove swirls, remove water spots, and remove scratches with ease. Microfiber is good for initial cutting where its slightly more aggressive design makes it more efficient for cutting than foam.

Polishing

Microfiber is an ideal pad for polishing because it has more aggressiveness to cut through clear coat more quickly than foam, yet not quite gentle enough to use for the finest finishing. A microfiber polishing pad is a fast cutter and a great polisher as well as easy to use.

Finishing

Microfiber pads are not exactly great for finishing. Although not as aggressive as wool pads, they still have cutting ability and will not give you the silky, smooth finish you crave for your car. It’s always advisable to finish with foam.

When Do I Use

Microfiber Pads

If you need an intermediate pad between the aggressiveness of wool and the gentleness of foam, microfiber is the pad for you. Microfiber’s cutting ability can remove heavy swirls and scratches with ease. The benefit is that they are not as aggressive as wool pads so you have less risk of burning all the way through the clear coat.

Microfiber Pads

vsFoam Pads

Microfiber and foam work well together. For jobs when you don’t need to remove heavy defects from your car’s exterior, but still a big job to tackle, microfiber and foam can work hand in hand.

Just start with the moderately aggressive microfiber pads for their cutting ability and finish with the low aggressiveness of the foam buffing pads for their smooth finishing ability.

Microfiber Pads

vsWool Pads

When you have heavy scratches and defects to remove, wool is the buffing pad to use. Microfiber is a little less aggressive than wool, so they are good as polishers once you’ve used wool for the removal of materials.

For those big jobs, start with aggressive wool buffing pads as your remover and move on to microfiber as a polishing pad. Keep in mind that to get the smoothest finish possible, you will have to incorporate foam buffing pads as well. Neither wool nor microfiber can finish as smoothly as foam.

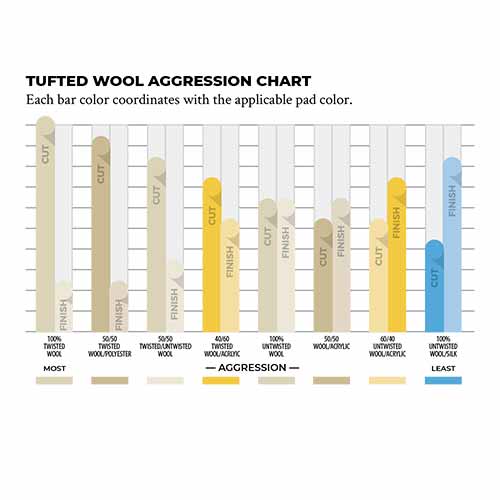

Wool Pads

Wool pads are aggressive. These pads boast strong cutting power good for removing scratches and oxidization from your car’s finish.

Cutting

Wool pads are more abrasive than foam and are considered cutting pads. They cut deeper into car paint layers than foam and can remove deep scratches and thick layers of dirt from your car’s surface. They are also excellent for paint correction.

Polishing

Polishing with wool is not for the beginner. A wool polishing pad is aggressive and has strong cutting capabilities. Wool polishing pads cake up quicker and transfer more heat to the surface than foam. Take great care if using wool as a polishing pad.

Finishing

It’s not that easy to use a wool pad for finishing. The fibers are abrasive so it’s difficult to get a smooth finish. It’s probably a good idea to finish up with a foam finishing pad and polish to smooth out any imperfections remaining from the wool fibers.

When Do I Use Wool Buffing Pads?

Wool is an aggressive pad and is certainly not for the finishing portion of your buffing job. Use wool at the beginning of your buffing job for heavy cutting to remove wax, dirt, paint, or sealants that you want to buff off the exterior. While you should be careful when using wool because of the aggressive nature of the material, if used correctly, it is quite efficient for removing stubborn materials and will work a lot faster than foam.

Wool Buffing Pad vs Foam

Wool pads are very aggressive and the right choice for cutting purposes like removing stubborn wax, dirt, paint, or sealants from your car’s surface. For polishing, you can use wool, but experience is the key since using wool polishing pads can lead the beginner to take off more than is applied. As a finisher, wool is not a good choice. The abrasive fibers will not give your car a smooth finish.

Foam is not very aggressive and can be used for cutting purposes like removing a watermark or lighter scratch, but will make for a longer work time if you are attempting to remove more stubborn materials. Foam works well as a polishing pad, especially with polishes that have a lower level of aggressiveness. Foam is great for finishing and will give your car a smooth finish because foam finishing pads have no cutting properties.

Wool Pad vs Microfiber

Wool is the most aggressive material that can be used as a buffing pad. While microfiber is less aggressive than wool, it is still not as gentle as foam. If you need strong cutting abilities in your buffing pad, wool is the way to go. It can cut through the most waxes, and scratches and is a go-to for paint correction.

Microfiber as a buffing pad is not as strong a cutter as wool and not as gentle as foam, so it is more fitting to be used as a polishing pad. It has just enough cutting ability to remove unwanted paints and waxes from your car’s exterior while still being gentle enough not to cause unwanted damage.

Frequently Asked Questions

You’ve learned a lot about buffing pads and it’s a lot of information to take in. It’s only natural to have some questions as you digest all this new learning. Here are some of the most common questions about buffing pads answered for your convenience.

How Many Pads Do I Need to Polish a Car, Truck, or SUV?

This is not a simple question and there is no specific number of pads as an answer. Some things to consider are the extent of your project, the condition of the surface of your car, and your expectations of the finished job. Some experts recommend two or even three buffing pads per stage of the job.

In other words, three pads for cutting, three for polishing, and three for finishing. The number of pads you choose to have for each stage will depend on your experience with buffing pads. Less experience means more pads while more experience means fewer pads.

And definitely don’t overwork or force the buffing pads to complete the job if they are worn out. This will lead to extra time and work to remove any damage the overworked pad has caused. Better to invest in more pads than spend time and effort correcting mistakes that you didn’t need to make in the first place.

How Long Do Polishing Pads Last?

A polishing pad’s lifespan depends on the type of pad as well as the pressure the user exerts on the pad.

Cutting pads have the shortest lifespan since their abrasiveness wears away with use. Polishing is next since they have less cutting ability and less abrasiveness to wear away. Pads for finishing last the longest since they are the smoothest and have little to no abrasiveness to wear away.

The pressure you exert also affects lifespan. If you have a strong touch, you’ll be replacing your pads more frequently. Those with a light touch will have pads that last longer.

When Do I Need to Clean Polishing Pads?

Over time, pads used for buffing and polishing absorb oils from the polishes used with the pads. They also get saturated with the paint that was removed from your car while you are polishing. With all of the saturation, the buffing and polishing pads lose some of their efficacy. You might also see splatter coming from the pads because the polish and paint have permeated into the pores of the pad.

In addition, you will notice that a section of your car that you polished earlier does not look as good as a section you recently polished. If this is the case, it’s probably time to clean your polishing pads.

How Do I Clean Polishing Pads?

When you’re ready for cleaning your polishing pad, you can follow these steps. First, prepare the pads by spraying them with an all-purpose cleaner. If you are not ready for the next stages at the moment, you can keep the pads in a plastic zip-lock bag so they don’t dry up.

Next, soak the pads in a polishing pad cleaner or some type of cleaning solution. Soaking will help loosen up the dirt and particles. You can also soak them in your sink with warm water and a small amount of dishwashing liquid.

After soaking, you’re ready for the rinsing phase. Open your faucet and lightly rub the polishing pad to remove dirt and unwanted particles. Continue rinsing until the water is clear.

Finally, you’re ready for the drying phase. This consists of squeezing as much water out of them as possible. Once you’ve removed as much water as possible, put your clean buffing pads in a warm place so they dry out completely.

How Do I Store Polishing Pads?

Dried polishing pads can be stored in zip-lock bags. Just make sure to separate the different types of pads according to their use. You don’t want a pad used for cutting to be stored with a finishing pad or you risk the contaminants from the cutting pad getting on the finishing pad.

What Is the Best Type of Car Polisher?

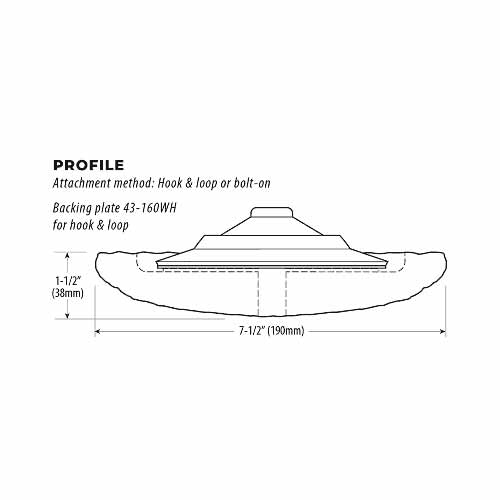

The purists out there may prefer to hand polish their cars, but that takes a lot of time and dedication. Machine polishing helps you to do the job quickly and efficiently. There are two types: dual action orbital polishers single action rotary polishers.

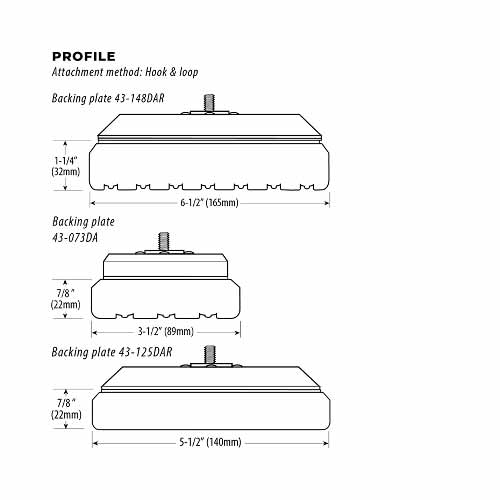

The best type of polisher may be a matter of personal preference, but the easiest to use and the best for a beginner is a dual action orbital polisher.

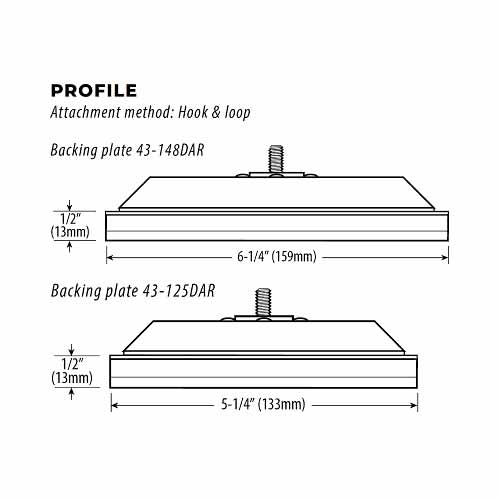

A dual action orbital polisher’s pad and backing plate spin in different directions. These polishers are suitable for light to moderate defect removal. They are typically used with foam and microfiber pads.

The learning curve on dual action orbital polishers is low, so these are great for beginners. The safest feature is that the more pressure you apply while polishing, the slower it spins so there is no chance of building up too much heat and harming your car’s paint job.

Rotary polishers (also called a rotary buffer) move in a circular motion in a single direction. They are good for the fast removal of moderate to heavy swirls, defects, and sanding marks. While wool and foam are most commonly used with these polishers, microfiber is sometimes used as well.

Rotary polishers are more difficult to use than orbital polishers because the pad friction generates heat. If too much pressure is applied or if you keep the pad in one place too long, you could create burns or swirls in your car’s exterior.

Using a rotary polisher takes practice and the learning curve is high. However, if you are experienced with these polishers, they make for quick work.

Helpful Links

Conclusion

Hopefully we’ve demystified the different color pads and the purpose of the different pad materials. Also, if you’re using a dual action polisher you’re going to be using a very safe tool that will help prevent you from removing more clear coat than you intend or burning the paint.

Now that you have the basic knowledge, it would be a good idea to pick up a pad kit and try them out for yourself to get a feel for how they work. You’ll get the hang of it in no time and have all of those paint defects removed in no time.

Foam Pads" srcset="https://detaildiy.com/wp-content/uploads/2022/01/78-52350CCS-76M-ccs-cutback-random-orbital-pads.jpg 500w, https://detaildiy.com/wp-content/uploads/2022/01/78-52350CCS-76M-ccs-cutback-random-orbital-pads-300x300.jpg 300w, https://detaildiy.com/wp-content/uploads/2022/01/78-52350CCS-76M-ccs-cutback-random-orbital-pads-150x150.jpg 150w" sizes="(max-width: 500px) 100vw, 500px" />

Foam Pads" srcset="https://detaildiy.com/wp-content/uploads/2022/01/78-52350CCS-76M-ccs-cutback-random-orbital-pads.jpg 500w, https://detaildiy.com/wp-content/uploads/2022/01/78-52350CCS-76M-ccs-cutback-random-orbital-pads-300x300.jpg 300w, https://detaildiy.com/wp-content/uploads/2022/01/78-52350CCS-76M-ccs-cutback-random-orbital-pads-150x150.jpg 150w" sizes="(max-width: 500px) 100vw, 500px" />

Microfiber Pads" srcset="https://detaildiy.com/wp-content/uploads/2022/01/MF-325-CUT-microfiber-pads.jpg 500w, https://detaildiy.com/wp-content/uploads/2022/01/MF-325-CUT-microfiber-pads-300x300.jpg 300w, https://detaildiy.com/wp-content/uploads/2022/01/MF-325-CUT-microfiber-pads-150x150.jpg 150w" sizes="(max-width: 500px) 100vw, 500px" />

Microfiber Pads" srcset="https://detaildiy.com/wp-content/uploads/2022/01/MF-325-CUT-microfiber-pads.jpg 500w, https://detaildiy.com/wp-content/uploads/2022/01/MF-325-CUT-microfiber-pads-300x300.jpg 300w, https://detaildiy.com/wp-content/uploads/2022/01/MF-325-CUT-microfiber-pads-150x150.jpg 150w" sizes="(max-width: 500px) 100vw, 500px" />